Scale Matters

Son of 1/2-A Operations

By Orin Humphries

November 2017

Inconsistent runs

In my first piece on these tiny engines I addressed every problem I was aware of up to that point. As you saw, these dealt with starting and sustaining engine runs into successful liftoff. That wasn’t the whole story, I was to find out. What about the second half of the tank?

All the while as I resumed flight this year, my .049 engines were troubled by inconsistent performance. They would run okay for half a tank and then they would sag randomly until starvation. That happened back when the weather was cold and I was on Traxxas fuel. I added castor oil to that mix and the problem went away. Lately I have been investigating this situation using Cox fuel with no luck until a recent morning.

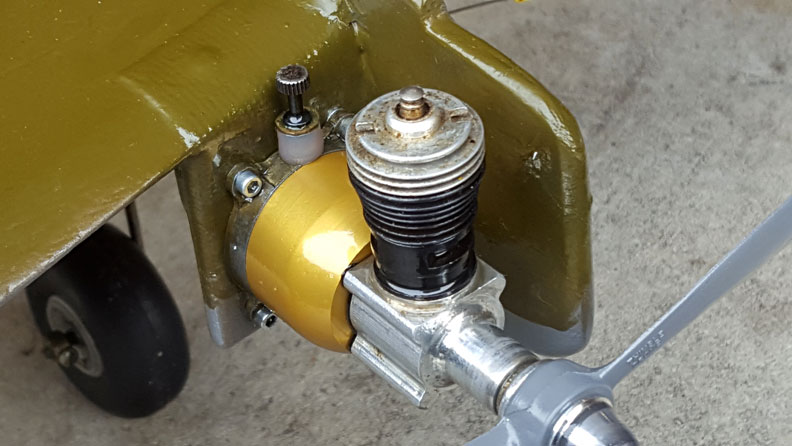

Along the way I went through every engine on my two twins (pictured above), the B-25D and the Blackbird YF-12A (first version of that line). To maximize the likelihood that you will get my current excellent runs, I must describe in tiny detail what I did and the configuration of the Cox engines, nothing fancy.

- They all got completely new gaskets and reeds, of course.

- Two got new Golden Bee tanks as the originals had been in hard landings and had their bottom pipes bent. I had sealed those with red RTV rubber, but they started leaking as I worked on them. I got parts from Cox International of British Columbia.

- I installed new fuel pickup tubes and springs to put factory parts there.

- The pickup tubes bent around in factory fashion to end up tucked into the back plate in factory location, 7:30, as seen from the front. This, I conjecture, may act kind of like the baffles in old VECO stunt tanks.

- Needle valves on all engines leak air and lower the vacuum without special attention. I sealed these NV’s by removing the springs and replacing them with fuel tubing and a washer on top of the tube (photo below).

- Finally, it is the fuel.

Reeds and retainers

Cox International states that the new reed shape, race track, is better than the copper star reeds of old. These new oblong reeds come in a variety of materials, and Cox Intl. states that the mylar ones “are the best ever.”

Everything on the front end of the new tanks is different. Gone are the spring and the groove for it in the extension on the front of the tank. The separate gasket is gone. There is a new combination gasket/reed retainer made of plastic that slips over the front extension. On my new tanks I randomly chose to orient the mylar reeds long way vertically. (That can’t make a difference.) But I then chose to orient the retaining pegs on the new retainers vertically also. That is, the retaining pegs are on the long axis of the reeds rather than crossways. I don’t know if that matters. I’m just sayin’.

Two of my tanks are still the old style with spring retainers, but they do have the new mylar reeds. This works, although my first blow test of these was unsatisfactory. A second blow test made them work as planned.

I had these four engines off, apart, and back on the Twins four times, taking care of details that were not completely addressed in previous work. One tank had a home-made venturi gasket from fuel tubing. Most tanks did not have the fuel pickup tube tucked back into the back plate. Some fuel tubes were too short, others too long. A fifth time disassembling the engines address that. They all have factory pickups, now. There are two sizes of fuel nipple for these pickup tubes, depending on the style and version of tank, and there are two sizes of tubing. All the while, when successive runs gave inconsistent performance, a voice in the back of my head was saying, “The fuel is a variable.”

Along the way I have been sending emails to “Dear Zoot” (Zoot Zoomer, you know …) asking for advice on these inconsistent performances I was getting on two or three of my four active engines. He offered that inconsistent performance in reed valve engines is the bane of Mouse Race, which requires the reed style for power. He said that “Some claim to have solved the problem,” but he was very unconvinced of that.

I told him that I had recently run a Cox Medallion engine for my first time with front venturi style. The Medallion engine’s consistent run surprised me, coming from nothing but trouble with the reed type. Zoot offered that basically, we might be asking too much of reed valve technology, best guess.

After my fifth time through the four reed valve engines on my Twins, and with no consistent runs in most of them, I was literally ready to abandon reed valves forever. I was ready to spend some serious funds to switch my Twins from reeds to Medallions.

Fuel

“The fuel is a variable.” My first article talked about nitro content and temperature, so I won’t address that again, here. In the warmer summer weather I am using “Cox Super Power Fuel” that I got at Galaxy Hobby in Lynnwood, Wash. Its oil is said to be 20%, 10% synthetic and 10% castor. When I first opened the bottle I added some Sig castor to it to bring it up to 20% castor. As said, I got inconsistent runs most of the time. The sags occurred after the first half of the tank had been burned and the engines were up to temperature. Clue, there.

On my recent test day. I marked the fuel level in the Cox bottle which came to 5 inches up on the side. I then added 0.5 inches, 10%, of castor to the bottle, this being the second time for that altogether. I had put off doing this a full day, not wanting to rub my nose once again in “The Mystery.” I had wasted too many of the Minutes of My Life on these reed rigs by now and too much money.

The first engine, No. 2 on the B-25, ran out a tank of the new mix beautifully! So what: That had happened to at least one of the four each session in the past. I fueled and ran the -25’s No. 1. I got another great, consistent run! So what, again; I still had the YF-12’s pair to go.

All four engines gave the first-ever, in this time, consistent runs.

During the composing of this article, I went online and looked up this Cox Super Power Fuel, a MK II formulation. A blogger named Rusty told that the Mk I version of this fuel had been very bad with the oil being 10% castor and 90% synthetic for a total of 20% of the fuel mix. His group got the formula changed to half and half castor and synthetic. He stated that this gave “the best ever runs.” Well, I noted that he did not give specifics about what to him was “the best ever.” For me, even with the first addition of some castor, I have had unacceptable variation in output. The engines were getting too hot and the clearances between the piston and cylinder were changing, causing the sags.

- All the while, I had taken to tuning my engines with a tach, mind you. This was not a guess fest on the needle valves.

- I was tuning them with the clip off.

- These Cox reed valve engines require 30% castor. This is just like the McCoys and Foxes with their steel liners and cast iron pistons.

Let’s look at that. Cox engines have steel cylinders and iron pistons. Why should we think their castor needs would be any different than the Foxes and McCoys?

This has been a Classic Mystery for me. I looked at everything other than what turned out to be the final solution first. And when I find the solution, it seems like a forehead slapper.

And by the way, it would appear that the manufacturer of Cox Super Power Fuel and its MK I predecessor does not fly their product, or at least their fuel. They only make a guess as to how to make the fuel and then sell it. Rusty said that they resisted customer complaints to improve the product until the weight of evidence and pressure from a distributor forced it on them.

I will grant you that my four reed engines do not constitute a statistically significant sample. However, it should be noted that one of my engines was assembled from components; this worked for factory engines and a components engine. My solution, then, seems to be a candidate for “universal.” Let me know if you are still having problems.

Remember how these engines slobbered all over our planes in the old days? Present fuel formulations don’t do that, and it looks odd to us old timers. Now, with enough castor in my fuel to run my .049s consistently, I am getting slobber again. Seems like home.

Best of luck.

Flying Lines home page

Back to Scale Matters column main page

Back to Scale main page

This page was upated Nov. 22, 2017