A View from Broadway

Frankenstein

By Ken Burdick

It's aliiiiiiiveeeeee!

Bringing the LA .25 to life

Yes Folk's, it's true.

It is alive and is known as Frankenstein. What was once dead has been given a creative spark of life.

I was not at all satisfied with what the stock O.S. LA .25 had shown me, and it did a little better with some simple modifications, but I wanted more from my Northwest B Proto Speed (Geezer Speed) engine. Willie Dixon wrote it, Howlin Wolf sang it ... “Baby, you got to take your time, I'm built for comfort, I ain't built for speed." That's exactly what we have with this engine.

“What I do, where I go, to get on outa here”

Thank you "Mac" Rebennack.

To get a sport engine up to my expectations for a pseudo speed event, it is going to take some machine work. This engine has room for more intake porting on the liner since much of it is uncut cylinder wall. To do this takes knowledge and the right machinery. I think there is a way to do it with the tools I have, but I'd rather have someone with the proper milling tools to cut into a liner for me. So lil' geezers, welcome to the outer edge of the envelope let's jump in and get on outa here!

Move OVER Rover, and let Hippie take over!

(Hendrix went to my high school, I get to say that.)

So Kennyb showed you how to get to 100 mph with sluggo the motor, right? Now let's get weird ... break out the Ouija boards and conjure up the Fast Hippy!

Unbeknownst to most, Fast Hippy (Marty Higgs), Kennyb, Bob Whitney and Batman (Bruce Tunberg) have been working on the engine from different angles, and sharing knowledge. Steve Walther, aka Salty, has been in on the deal and holds all bench rpm records with his engine, but only after Marty added subport induction. In trying to make a blueprint for this motor, the hippie and I agreed on many things that could be done to improve La dead body, and one of them was this: Add a third port. First, we tested our other ideas on it, cylinder head, subport induction and, we opened up the crankshaft timing. All these things contributed to the current improvements. Now lil' Geezers, we want to add a third intake port to this monster and see if we can really make it live.  First things first -- just how to do it.

First things first -- just how to do it.

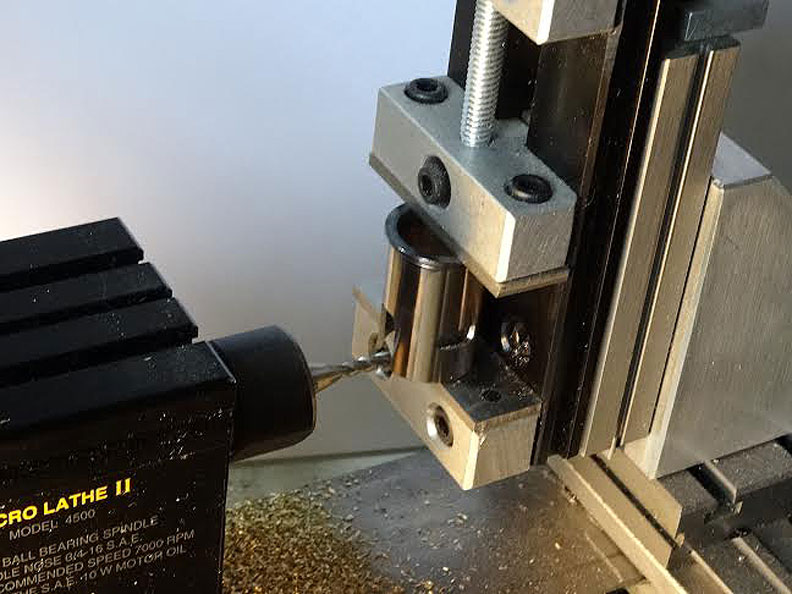

Several ideas were kicked back and forth on how to accurately produce the third port. Batman was cautioning against doing it without the proper machinery, so that left me out. I had designed a “wart” based on a Picco 21, to be epoxied to the case and creating a boost port using lost wax tooling, and porting epoxy. The really hard part is to cut the liner with accurate ports. It was Bob Whitney who came up with the very simple idea of cutting a slot into the liner from the bottom up to the height of the other ports, creating a channel for the fuel to follow, a bit like the old Perry porting back in the day. The Cyclon engines are an example of this idea, but uses EDM to cut a precise shape into the thick aluminum liner creating the channel we are used to seeing molded or cut into the crankcase of most engines.

Slot Machining

The Fast Hippie did the slotted liner, and then some. He machined a .30 wide slot, from the bottom of the liner to the same height as the existing ports. The LA 25 is different than most engines in that the collision of fuel in the chamber collides sideways and not angled up at the head. Marty matched this angle on the third port.

Getting a head

Every monster needs a head -- otherwise it can't see where it's going, right? Here are some of the details on how The fast Hippie put a head on Frankenstein.

The head work is a bit more intricate than ol Kenny's and this is what he did for Frankenstein series:

Starting with the stock head, remove .045 from the chamber height and lap it smooth. Inside the combustion chamber, put a small indent with a 3/8” tool to create a double bubble where the glowplug hole is, but more importantly to make the bottom of the glowplug flush with the combustion chamber. The head now will need to use a short glowplug or space a long so the bottom of the plug is flush with the chamber surface. Next set the head to .010 from the piston by removing material from the head to liner surface. To do this, the head was machined to .00 clearance from the piston, and raised with a 0.10 head shim. By using head shims we know exactly where the head is to the piston.

We need the bump ... gotta have the bump

All disco tunes aside, Marty honored the great men of speed by adding additional liner work and to machine the exhaust port for a Wisnewski/Nelson style bump centered along the upper edge of the exhaust port. It is approximately 3/8” wide and .020 high. This will give us slightly higher exhaust scavenge timing.

Notes from the lab

Notes from the lab

In a rare disclosure, here is communication from the one and only Fast Hippie

Ken, here's some info on the FRANKENSTEIN MK-1 the head had .045 removed “lapped” from the squish band to increase it's size, it's now about 50% of the head, also I cut another bubble right at the plug, much like the Nelson head but this requires an extra glowplug gasket to raise the plug higher. As for the third port, it is the same width as the stock ports and is cut to the same intake timing feature, I feel there is room here for more timing !?!?

“You promised a monster ... "

Did not ... Yes, you said Frankenstein!”

"You really don't want to open that bag ..." WE WANT A MONSTER!”

Well okay, don't say I didn't warn you.

Frankenstein MK-2

Here is a picture of Frankenstein MK-2. Its heart is truly beating faster than previous efforts, here in the dungeon when we turned up the voltage and it just started moving ... faster!

It's very similar in work to Frankenstein MK-1 but it has about .010 of sub port induction across the bottom of the piston, in the exhaust port. Again, there is a “bump” milled into the liner for that little bit more exhaust timing, the work is beautiful!

Frankenstein 2 was made to not be run with a mini pipe so open port it is.

More secret stuff

The prop

7x8

Bula babies, I said it in Article 1, focus on the prop for top performance. It bears repeating, so here is a closely guarded secret. Bob Whitney aka F2c Racer, has been making props for this event and I was the guinea pig -- some kind of pig anyway.

Hoarding information is stupid unless you are making a living from it; even then it's going to be temporary. OK. So let's have it. The prop I have been using is a winner, and nothing short of excellent. It comes from a vintage era and has been molded into a perfect tool for this event. Back when they used to race pterodactyls, there was a series of Tornado wood “plastic cote” props. Man, they were works of art. Nothing like what you get today.

Anyway, it's none other than the third conspirator Bob Whitney who mumbled something like “might have sumptin' in the shop for ya.” A week later, he had made the first carbon copy of this little gem. And ... it's the very same prop that I went hopping up and down with at the NW Regionals championship with, and ran 100 mph since then. It's a sweet running carbon fiber handmade prop, and it's sure to get you hummin'. I recommend this prop to all flying G-Speed. Contact your local Bob Whitney and buy a couple. This is the stuff records are made of, lil' geezers. Iit didn't just happen along -- it has to be handmade. You will want to work on it to get what is right for you. Thin the blades and add your favorite tweaks and diameter, but it's a great place to begin.

RPM testing Frankenstein 1

All with 10% Power Master blend 20-22 oil and short O.S. glowplug.

| Kenny B's engine | ||

| 7x8 Rev-Up | 17,100 | 18,000 |

| 8x6 APC | 18,000 | 18,000 |

| 6.75x7 | 19,100 | 18,500 |

| 7x3 | 26,500 |

| 7x8 | 17,000 |

| 8x6 APC | 18,000 |

| 6.75x7 | 19,800 |

| 6.25x7 | 20,250 |

k1. (no liner shim, head set at .012) Kennyb's engine (without mini pipe)

7 x 8 rev up 17,100

8 x 6 apc 18,000 18,000

6.75 x 7 19100 18,500

7 x 3 26,500

Frankenstein MK1 with Raised liner .010. Head set at .012

7 x 8 17,000

8 x 6 apc 18,000

6.75 x 7 19,800

6.25 x 7 20,250

I'll break in Frankenstein 2 and send in the results soon. A consensus is that it will run the 6.75x7 over 21,000. Remember, lil' Geezers, this is a bench prop so our flying prop will still be around 7x8. A good bench prop will tell you if the changes you just made to your engine are valid, and with some luck will emulate flying RPM.

Problems and solutions MK-2

I'd like to say that all went smoothly, but it didn't. From the first, Frankenstein MK-2 was touchy to the needle settings. The break-in fuel had about 30% oil and was 10% nitro. The Bladder tubing was yellow jacket I use for combat wings so it's really been tried and approved by Bod Busters all over the world. The problem was when I tried to run it rich, it would rapidly fall off and flame out. Many things COULD be the problem. It seemed to run fine wide open but I wanted break in and up till now, none of the other engines had displayed this. I tried different fuel, same results. Different heat range of glowplug, same results. Added .005 to the head, same results. Put a pressure reducer in the fuel line, same results. The setting would change dramatically with one or two clicks of the stock needle valve. I changed back plates to a known working needle valve, same results. My thought was that maybe, just maybe, we had found the outer limits of the head/ compression ratio. I then did what any good Bod Buster or Beaver would do -- I put together a combat wing for test flights. I used one of my team trials models with aluminum mounts modified for the LA .25. It makes a handy test run fixture and -- you can fly it too! First things first -- why won't it run rich?

I changed heads from my #1 engine that Batman had reworked. It is milder and proven to be a good combination that I can count on. I set the head at .015 from the piston and fired it up. The rich run was there! It WAS the head. Next I flew it using my nifty launcher. Lots of power was my first thought. I was using an APC 8x6 sport prop and the engine just sang. I put a stopwatch on it and clocked well over 100 mph.! So the question is this: Will the Fast Hippie head work on this with a better needle valve assembly?

Partner (Chris Sackett) decided early on that the stock NVA was no good for him, I found up till now that it would work fine with a bladder system. We however, are now running a three-port engine with a Fast Hippie head. Soooo -- let's try a good needle valve. I think most all speed flyers agree that a good needle valve is Super Tigre. They can be purchased from Tower Hobbies for less than $10.00 and I happen to have one.

How to wreck a perfectly functional motor part

.To do this, I first thought I could press the brass body out of the plastic housing on the back plate. I was wrong and they must have molded the brass gizmo in place when they shot the part in the mold -- nada -- won't come out. Next I located the proper size drill bit and from the needle valve hole, drilled out the brass so as to insert the ST assembly into the hole. Unfortunately I broke part of the plastic in all this process. If you just drill the thing out, you should be able to bolt the st in place, and line up the spraybar hole with the plastic nipple. Very cool, lil' geezers. You get to keep the needle valve back there away from the prop and get a super fine NVA to go with it. I shamelessly covered up the missing plastic as well as the now to be deleted fuel-in nipple with good ol JB Weld. This may be a good idea for some who just don't want the stock setup. It unfortunately did not solve the issue of the double bubble head not being able to get a rich setting. For now, Frankenstein MK-2 will have the Batman head on it. To be fair, the Frankenstein MK-1 has a similar head and runs fine. The Fast Hippie has never had this sort of problem, soooo that leaves ME as a common factor. I just don't understand this engine. What I do understand, is the speed I recorded while flying this really cool bit of work from Fast Hippie. Obviously we are just scratching the surface, so as things progress, both good and bad; I'll keep you geezers in the loop.

Bench testing is really just for bragging rights and to see if the last thing you changed made any difference. The real deal is in the flying and stopwatch. So far, Frankenstein has only topped 100 mph in competition ands is a good 6 or 7 mph off the record. This is the fun of Geezer Speed….the doing of it. Proto is an interesting event that you can really experiment with. Partner tells us that the record engine is running a pressure tank, stock head set at .019 from the piston and a custom needle valve assembly from Doug Galbreath. Ol Partner'll keep kicking butts and takin names while we in the lab continue to experiment with this unusual engine.

Sources:

Prop: Bob Whitney

Needle valves: Tower Hobbies or Doug Galbreath

Good luck!

--Kennyb

See article 1 of the LA .25 rework series

See article 2 of the LA .25 rework series

Back to Bod Busters main page

Back to Speed main page

Flying Lines home page

This page was upated Oct. 19, 2015