Miscellaneous Stuff

Cleaning used engines

By Gene Pape

December 2022

In the past I’ve written about refurbishing engines that are in serious need of help. I’ve ended up with a lot of used engines lately. I buy them from eBay, get them as raffle prizes at fun-flies, and some are even given to me. Unless repairs are needed, I try not to take the engine apart.

First, take the needle valve assembly out. This is to allow access to the area between the venturi and the crankcase for scrubbing. I then rotate the engine clockwise until it comes up against compression. Both the exhaust port and the crankshaft port should now be closed. I then stuff paper towel pieces in both the venturi and exhaust port and saturate the paper towels with oil to prevent water from getting into the engine.

Now is when you start actually cleaning. I would use either Dawn Powerwash or a product called Oil Eater. Unless the engine is really bad, I try to use the Dawn Powerwash as it is easier on my hands and doesn’t make as much of a mess in the sink. If something stronger than the Dawn Powerwash is needed and you can’t find Oil Eater, go to an auto parts store and ask for something to clean off oil residue. I spray the cleaner on the engine and let it soak for about 15 minutes then scrub the engine with a toothbrush and rinse with hot water. You may have to repeat this several times to get all of the oil residue off. Some people use fuel as a solvent and while I've never tried it because of the mess I would make, I'm sure that would also work.

Once the outside of the engine has been dried, I finish the project by putting a prop on the engine then putting about 5cc of synthetic-oil-only fuel in the crankcase through the venturi. I slosh it around a bit them flip the prop several times. I then open the exhaust port and roll the engine around to pour the fuel out. The fuel will be a nasty brown color. Repeat this process until the fuel comes out clear. Finally, add a few drops of after-run oil in the exhaust port and several drops in the venturi and flip the prop several times to distribute the engine oil.

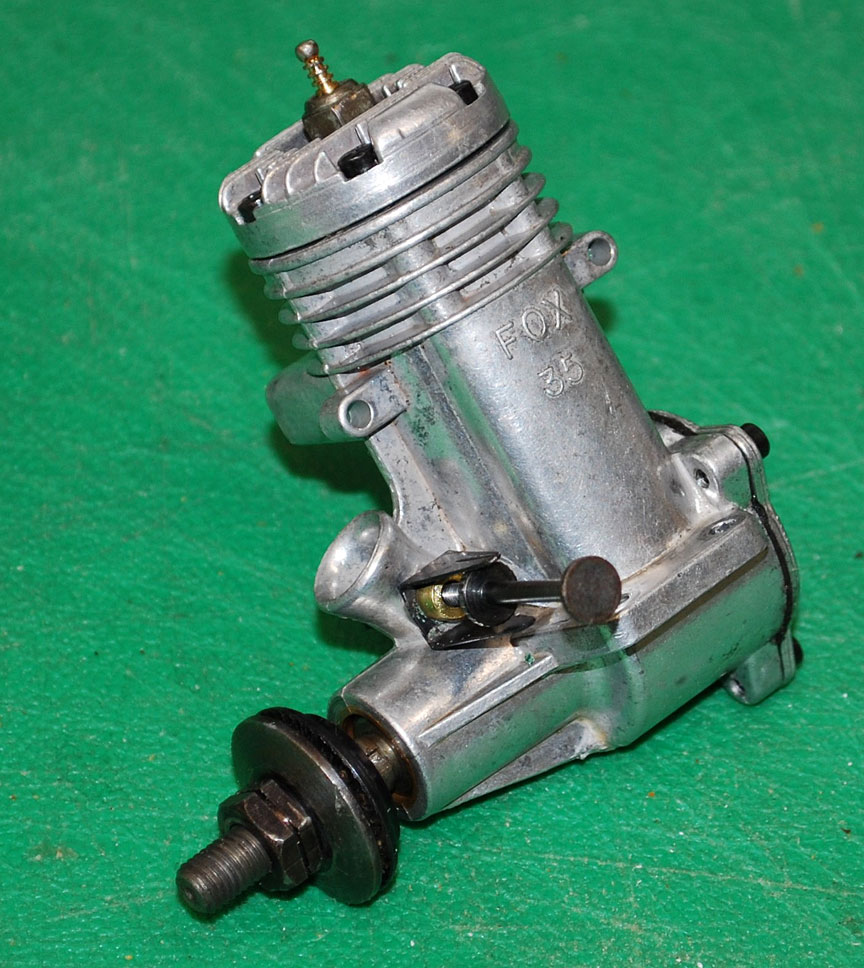

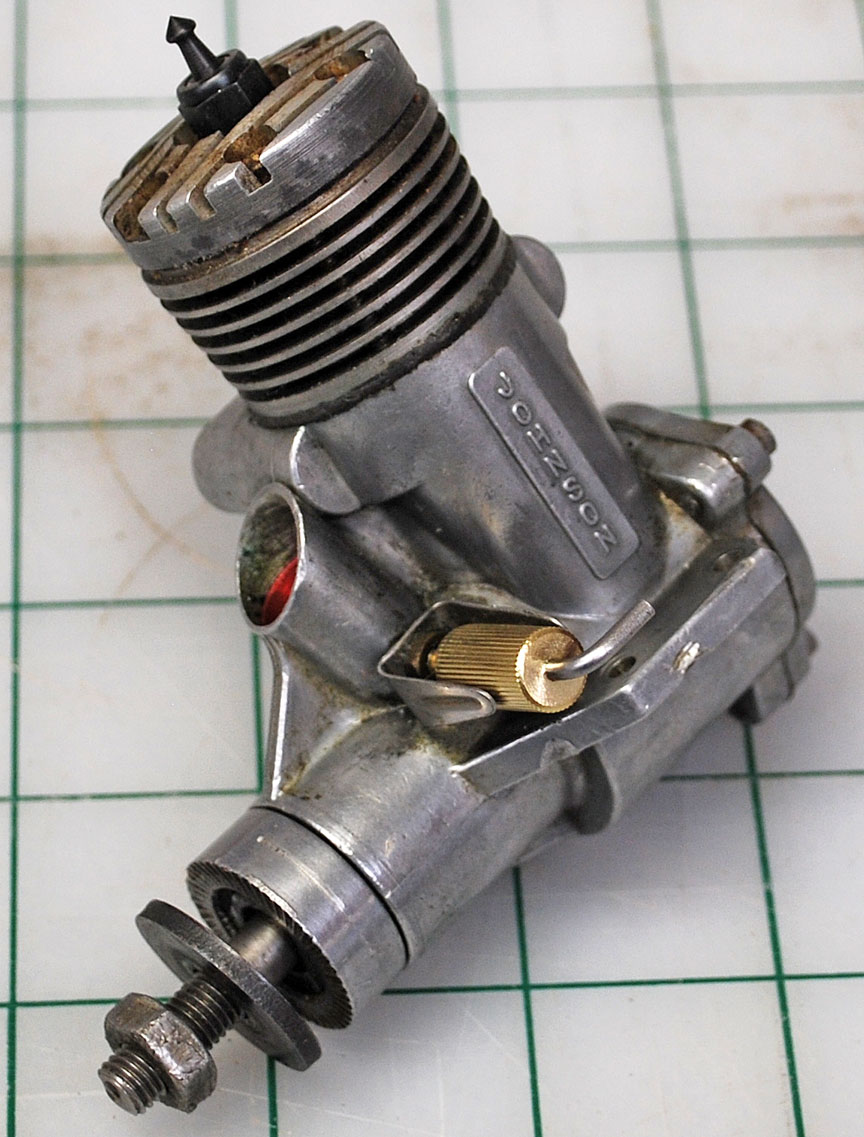

A Fox .35 Stunt engine, before and after cleaning as described above. All photos by Gene Pape.

Buying Engines on eBay

If you need a control-line engine these days, one of the few sources is eBay. Many of you have never purchased from eBay and plenty of you are reluctant to buy from eBay for fear of getting an engine that is no longer serviceable. Most of you will be buying engines for a particular need and a few people like me, while I tell myself I’m buying engines for future model project, buy engines from eBay mostly for entertainment. I hope this will provide tips for both kinds of modelers wanting to purchase engines.

You can buy with confidence

First, for those of you who want a high-quality engine without risk, there are three buyers that I have bought from who are very professional and knowledgeable: Kelly4440, Gatfish, and Modelenginegarage. They almost always get top-dollar for their products because eBay buyers have come to know them for their consistently high quality products.

Left: A Johnson .36BB purchased from Gatfish. Right: A Fox Combat Special from Kelly4440.

What to look for

If you’re more adventurous, here are some things to look for when buying an engine.

First, is it complete? If an engine doesn’t have a thrust washer, I almost always ignore it as replacement thrust washers for most engines are no longer available and you will have purchased a paperweight.

If the engine doesn’t have a glow plug in it you can ignore the seller promising that it has good compression.

I will then look at the condition of the screws holding the engine together. While the backplate screws are of some concern, most of us have removed backplates from engines to remove dirt from a crash. Damaged head screws tell me someone who probably shouldn’t have has at least tried to completely disassemble the engine. I have found all kinds of things wrong with engines from people working on engines. People who know what they are doing usually don’t damage screws.

Look for damaged mounting holes. This can be an indicator of how carefully the engine was treated.

Does the engine have the original needle valve assembly? This is a bit subjective as some needle valve assemblies get changed because another brand works better.

Is the engine clean? If it’s coated with burned-on oil It’s probably led a long hard life. Remember, most of these engines are being sold by people who know nothing about them.

Some examples

Left: A stock Johnson .35 Combat Special as it came from eBay. Note the stock venturi insert, needle valve and glow plug. Right: This nasty-looking Fox Combat Special was a good choice because it has undamaged stock Phillips head screws, original needle valve assembly, original drive washer and period-correct if not original glow plug. It cleaned up very nicely.

Cleaning needle valve assemblies

I have finally learned that when an engine sits for a long time the inside of the NVA becomes plugged with fuel residue. I just finished putting back together an engine that had been sitting probably more than 20 years. My normal procedure is to remove the needle, wipe it off, squirt fuel through the spray bar, the slightly insert the needle and squirt more fuel through the spraybar. Finally, set the needle. This is a good start, but it’s common for a bit of crud to remain and cause the engine to go lean during the next flight.

Hummingbird-feeder cleaning brush works well for cleaning spraybars.

Today I remembered I had a large supply of brushes for cleaning the ports in hummingbird feeders. I was able to remove the needle then clean it as usual then use one of these brushes soaked in synthetic oil fuel to clean the spraybar. You can’t believe the amount of crud I got off of the brush when I wiped it off after even though the hole appeared perfectly open when I looked through it. I’m expecting at least one of you to reply either that you’ve been doing something similar for years or that you have an even better method.

My take on oils

There is an old saying that goes something like this: I know you think you understand what you thought I said, but I’m not sure you realize that what you heard is not what I meant.

That’s kind of how I feel about everything I know and model engine lubrication in general. So, here’s what I think I know from what I think I’ve heard from a very large number of different sources:

There are two general kinds of engines. The old bushing crankshaft iron piston engines and the modern ball-bearing crankshaft aluminum piston engines. As a general rule, the old engines like castor oil and the modern engines like synthetic oil.

Castor oil is good at filling the gaps in the sometimes-too-loose fits in the older engines and can provide a bit of added lubrication under certain circumstances. It also has a tendency to leave behind varnish. This is both a good thing and a bad thing.

First the good things. Many of the early engines had pistons made from a porous kind of iron. They needed to have the varnish from the castor oil to seal the piston crown to provide adequate compression. In some instances, they also needed the varnish to fill the gaps in the piston to cylinder fit.

Now the bad things. The varnish buildup on the outside of the engines is not only ugly, it reduces the ability of the engine to shed heat, leading to overheating. The varnish buildup inside the engine can become excessive, causing lack of performance. This is especially a problem in modern engines with very tight piston-to-cylinder clearance. I have seen a modern engine lock solid from the castor oil buildup from using 10% castor oil and 10% synthetic oil in the fuel. A bit of cleaning and switching to using only synthetic oil has allowed that engine to still be running fine 12 years later. The very worst part of using castor oil is the sludge it leaves behind if the engine is simply put away after use without using some kind of proper after-run oil. I have purchased quite a number of engines from eBay. You cannot even imagine the mess left behind after simply putting an engine that was very thoroughly flooded with castor-oil-based fuel in a drawer then leaving that engine untouched for 40 years.

Synthetic oil is truly our friend. I have seen hand-written formulas from engine/fuel manufacturers from the 1950s calling for a certain percentage of synthetic oil in the fuels they manufactured back then. Synthetic oil has more lubricity and is much cleaner-running than castor oil. Modern engines are generally happier with only synthetic oil in the fuel. I say "generally" because the Fora ½-A engines seem happier if they have about 5% castor oil in the fuel mix. In any case, it seems to be a good practice if you use fuel with castor oil to run a small amount of all synthetic oil fuel through your engine after a day’s flying to get rid of all the sticky castor oil residue. This can be especially important in reed-valve engines where the reed valve will stick closed after a period of time if castor oil residue is left in the engine.

Now to after-run oil. Ask 10 people what they use for afte- run oil and you will get 10 different answers.

Two things I do not recommend.:

• WD-40. WD stands for water displacement. If you have been out flying on a very humid or rainy day, WD-40 is a good way to make sure the moisture is removed from the engine but be sure to use some kind of oil to then displace the WD-40, as it is mostly solvents and the residue left behind after the solvent evaporates will lock your engine up.

• 3in1 oil. This may be just my thing as I restored many classic bicycles and 3in1 oil was a standard thing to lubricate them back in the day. I have seen all kinds of lubricant residues in old bicycles and the worst was a nasty hard black residue that I determined to be what was left of 3in1 oil after several decades.

There are four kinds of oil that I have some experience with for after-run oil:

• Great Planes After Run oil. Very expensive, but also very convenient. I use it regularly and have found no problems with it.

• Marvel Mystery Oil. It has solvents in it and I use it if I think there may be moisture or contaminants of some kind in the engine. I usually follow it with some other kind of oil as it will dry up and become stiff after several months of storage.

• Automatic transmission fluid. Henry Nelson uses this liberally in his new engines before he ships them out and I’ve never seen any kind of problems from it. It also has a number of additives to deal with any contaminants that may be in the engine. My current favorite is Senco brand air tool oil. It seems to remain free running for a very long time. I have tried other brands of air tool oil that didn’t even work well in air tools.

• Sea Foam:

This is a product I just learned about from Gene Christensen on the Facebook Free Flight page. It’s for use in boat engines. This may be the best of all as it certainly has something to displace water and it has all kinds of solvents as well as lubricants. If you try it, let me know how it works.

At this point the only thing I’m fairly certain of is that it’s not a bad idea to use a generous amount of good quality after-run oil after each flying session.

Back to Miscellaneous Stuff main page

Back to Regular Columns

Back to Combat section

Flying Lines home page

This page was upated Dec. 20, 2022