A View from Broadway

Boris takes a breath

By Ken Burdick

Yes folks, it’s true.

Ever have a head cold? You know, the kind that just plugs up your nose and you can’t breathe? Well, Boris the D Speed engine is no different in my opinion, his ability to breathe was severely restricted by the pre-existing condition of rotorus-plugupagus. In other words, I didn’t like the rear induction system.

The stock Boris, an MDS10cc marine engine. Ken Burdick photo.

The design is okay except it weighs a ton and is restrictive, so I set out to modify the stock system with a much larger drum in the original housing, and lighten it up as well. If I did that, it would help but I would still have to deal with the air intake up on top of the assembly. This would require a remote needle valve and I just didn’t like it.

I bought some special alloy to make a new drum and about that time Dick Heart let me know that he had an OS .65 rear drum that he would part with. This is always risky trying to blindly assume that the thing might fit -- and it didn’t.

A big bag of things that wasn’t right

When the OS drum arrived, it looked too cool not to give this a try, but the list of things that needed change were daunting.

The drive pin on Boris is tiny compared with the OS drum drive slot and while the mounting holes in the housing were close, they didn’t quite make the pattern. Add to this that the depth of the assembly was more than the depth allowed in the crankcase and you need a knowledgeable machinist!

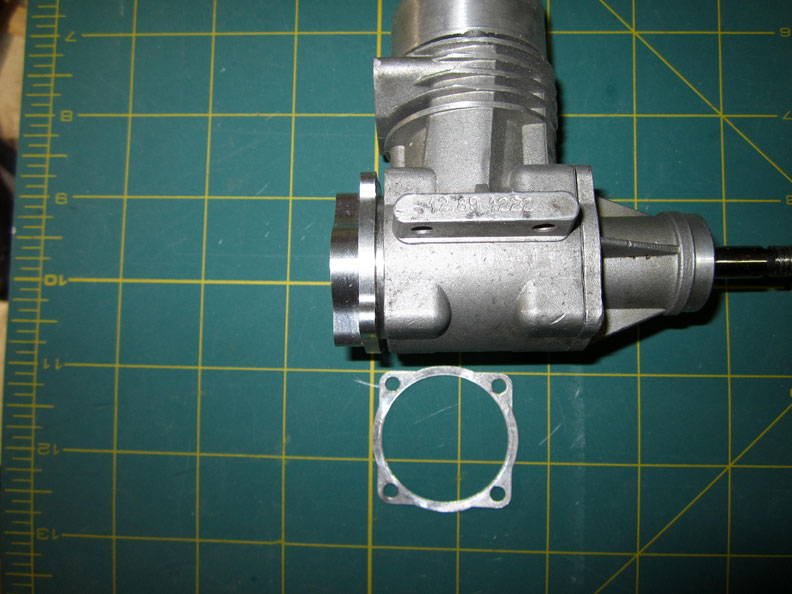

The rotor depth issue. Ken Burdick photo.

My choices were to try and make a larger drum myself and bore out the MDS housing, all doable, or figure out a way to make the OS drum work. Did I mention that the OS drum housing was a smaller internal diameter than the MDS? Lovely, just lovely.

I spent some time pondering the whole thing and then wrote to the Bod Buster’s best friend when machine work gets complicated,Doug Galbreath.

I told him what I needed and he said that if I REALLY wanted to do this, he would help. He would need to make a spacer for the housing, a sleeve to center the housing in the larger hole, make a venturi that bolts to the oval pattern devised by OS, and put a needle valve into the beast.

One thing that I could do myself was to correct the drive pin diameter. A simple sleeve Loctited to the drive pin worked perfectly. The drum it turns will hold it captive in the event the glue gets funky.

The drum parts. Ken Burdick photo.

Let’s review.

- Almost bolts up but no cigar, hole pattern is slightly off.

- Drive pin has .008 clearance in drive slot

- Dimeter of drum housing is too small to center in the crankcase.

- Crankcase is too shallow for the assembly even if it did fit.

- Needs a venture that will bolt to an oval pattern

- Needs a custom needle valve assembly.

Did I leave anything out?

Doug is an excellent machinist and motor man. He and I contrived to make the first Picco 1cc into a proto legal .049. It currently holds the 1/2A proto record. Doug also was the final touch on Richard Shannon’s C speed project that holds the fastest C speed time of 193 mph. Remember, C is a .40. -- wee -- small-- little -- s'fast! And Doug set the liner up for it. So when a Bod Buster is in need, Doug is who we turn to.

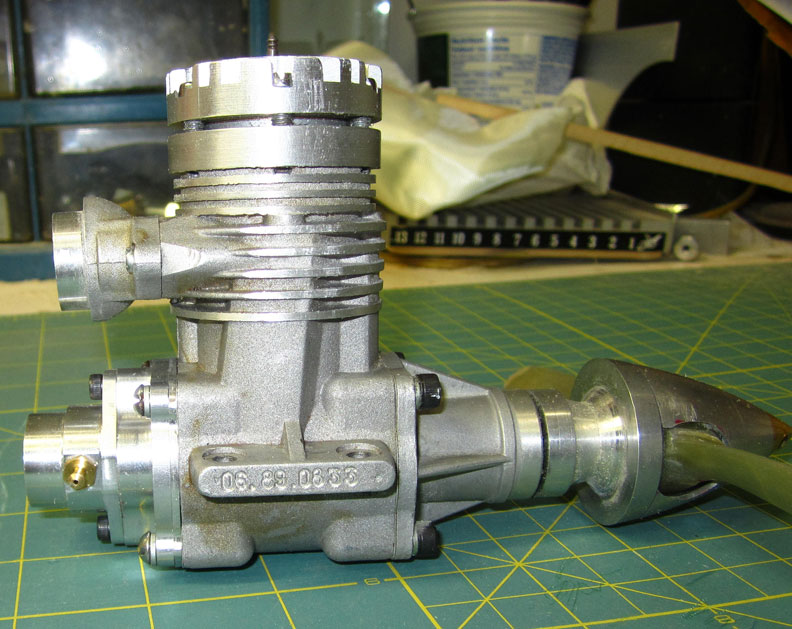

Boris with the finished drum. Ken Burdick photo.

Here are the final pictures of Boris with clear sinuses. Stay tuned to Flying Lines for a new and improved Louie-Louie D Speed mark.

Kennyb

Back to Bod Busters main page

Back to Speed main page

Flying Lines home page

This page was upated April 26, 2017